Die Marke centerdrill existiert seit über 20 Jahren und steht für präzise und wirtschaftliche Werkzeuge „made in germany“. Hier kaufen Sie direkt vom Hersteller.

Mit unseren Qualitäts Fließbohrern haben Sie eine spanlose Methode zur Erzeugung von Durchzügen gefunden (auch „Flowdrill Verfahren“ genannt). Wir ersetzen Einziehnieten, Schweißmuttern, Pressmuttern und das Gewindeschneiden in dünnen Materialstärken. Wie das genau funktioniert? Schauen Sie sich unser

„CENTERDRILL VIDEO“ an.

Mit unserem neuem „CENTERDRILL EXPLORER“ geben wir Ihnen eine Möglichkeit an die Hand, mit der Sie schnell und einfach den für Sie richtigen Fließformer ermitteln, oder auch mehr über Ihren bereits vorhandenen Fließbohrer (im englischen auch „Flowdrill“ genannt) erfahren können.

Bestellen Sie auch direkt in unserem „CENTERDRILL ONLINESHOP“! Hier finden Sie Fließlochformer, Gewindeformer, Fließbohrer Einsteiger Sets und noch vieles mehr.

Haben Sie noch Fragen? Wünschen Sie eine Beratung oder ein individuelles Angebot? Dann stehen wir Ihnen

selbstverständlich mit Rat und Tat zu Seite [zum Kontaktformular].

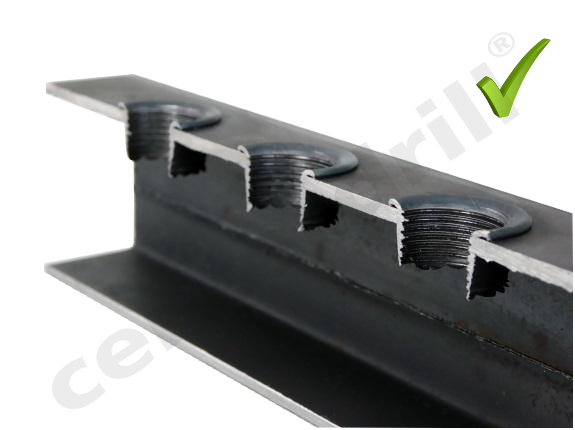

Mit unseren Centerdrill - Fließbohrern haben Sie eine spanlose Lösung gefunden, um eine stabile und hoch auszugsfeste Gewindebuchse herzustellen. In nur zwei Arbeitsschritten zum DIN-Gewinde aus dem eigenen Material.

Kein Wackeln, Lösen oder Mitdrehen!

Schweißmutter - Gewindeschneiden - Einziehniete

Lösen, zu wenig Gewindegänge, Mitdrehen

Die stabile Centerdrill Buchse

Oberfläche mit Kragen

Die stabile Centerdrill Buchse

Oberfläche ohne Kragen / plan

Sie erhalten ein geformtes und auszugskräftiges Gewinde aus dem Ursprungsmaterial in nur zwei Arbeitsgängen. Kein Wackeln! Kein Verdrehen! Kein Lösen!

Wir ersetzen mit dem Fließform-Verfahren (auch Fließlochformen, Fließbohren, Thermobohren oder Flowdrill Verfahren genannt) Einziehniete, Schweißmutter, Pressmutter und das Gewindeschneiden in dünnen Materialien.

Hier sehen Sie alles Wichtige zum Centerdrill - Verfahren auf einen Blick.

Das Fließbohren mit Centerdrill wird auch wie folgt genannt: Fließlochformen, Fließlochbohren, Thermobohren oder Flowdrill Verfahren.

Optimieren Sie jetzt Ihre Fertigungsprozesse. Wir machen es Ihnen leicht!

In unserem Centerdrill Einsteiger Set finden Sie alles, was Sie für den Start mit dem Fließbohren (auch Flowdrill-Verfahren genannt) benötigen. Jedes Set mit deutlichen Kostenvorteilen gegenüber dem Einzelkauf!

Stellen Sie sich Ihr Centerdrill Einsteiger Set in unserem Online-Shop zusammen, oder lassen Sie sich Ihr individuelles Angebot* von uns erstellen.

Sie wissen noch nicht welcher Centerdrill Fließbohrer der Richtige für Sie ist? Dann schauen Sie in unserem Centerdrill-Explorer nach!