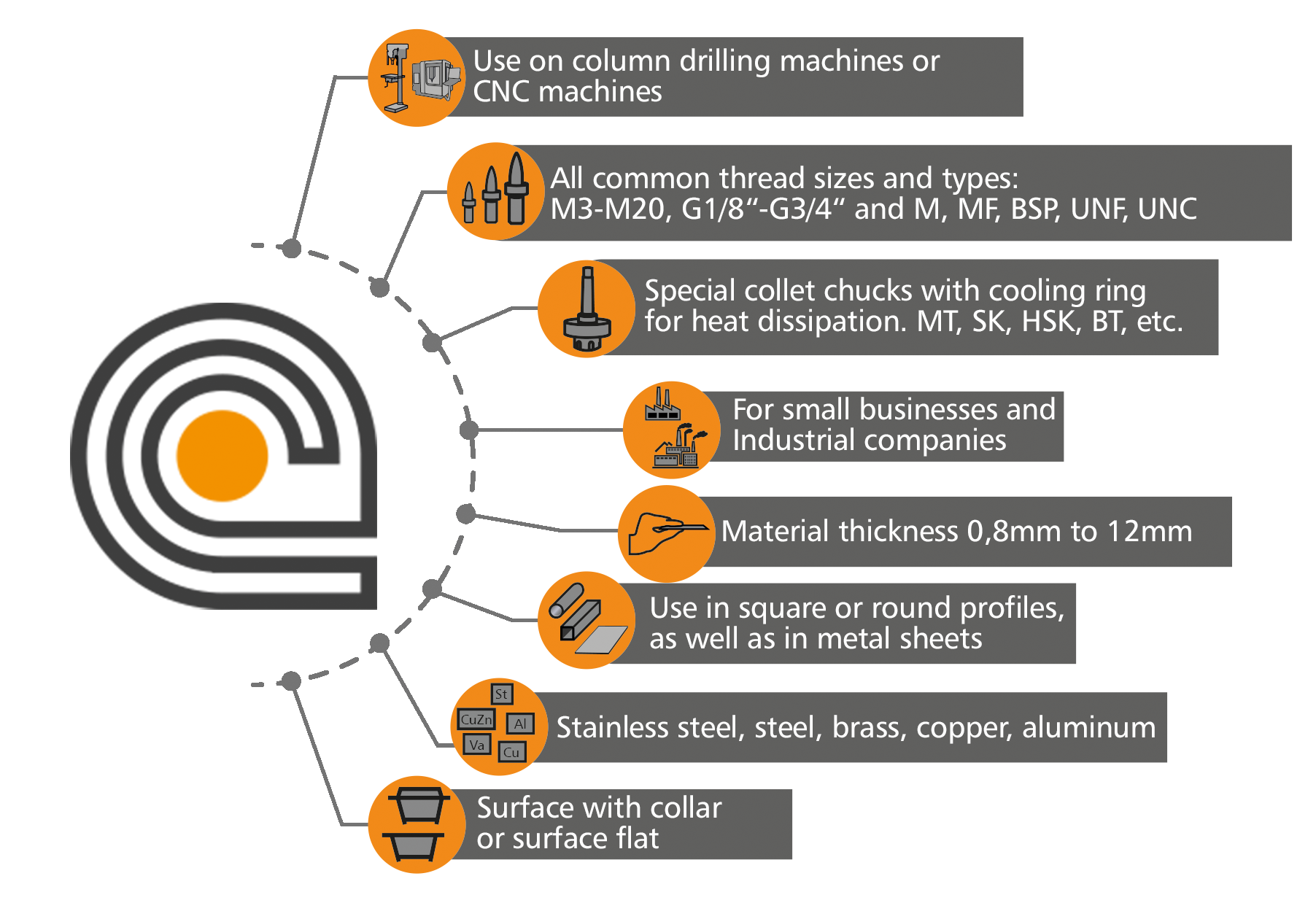

The Centerdrill flow drilling tool consists of special solid carbide and its special geometry allows producing long bushes in thin materials. With the flow drilling process (also known as Centerdrill, friction drilling, flow forming, thermdrill process, form drilling) we replace the rivet nuts, welding nuts and thread cutting in thin materials.

Centerdrill flow drilling in practice => Video

The Centerdrill tools are available in the diameter of 1.8 - 32.0mm. Under optimum conditions and depending on the type of material a lifetime up to 10.000 holes can be achieved. The standard centerdrills are suitable for material thicknesses from 0.8 – 12mm. The following materials can be processed: Stainless steel, steel, aluminum, brass and copper. After producing the hole/bush we will form the DIN-thread, as for example metric, metric fine or BSP, in second step. Generally all common thread types (M, MF, BSP, UNC, UNF, etc.) are possible.

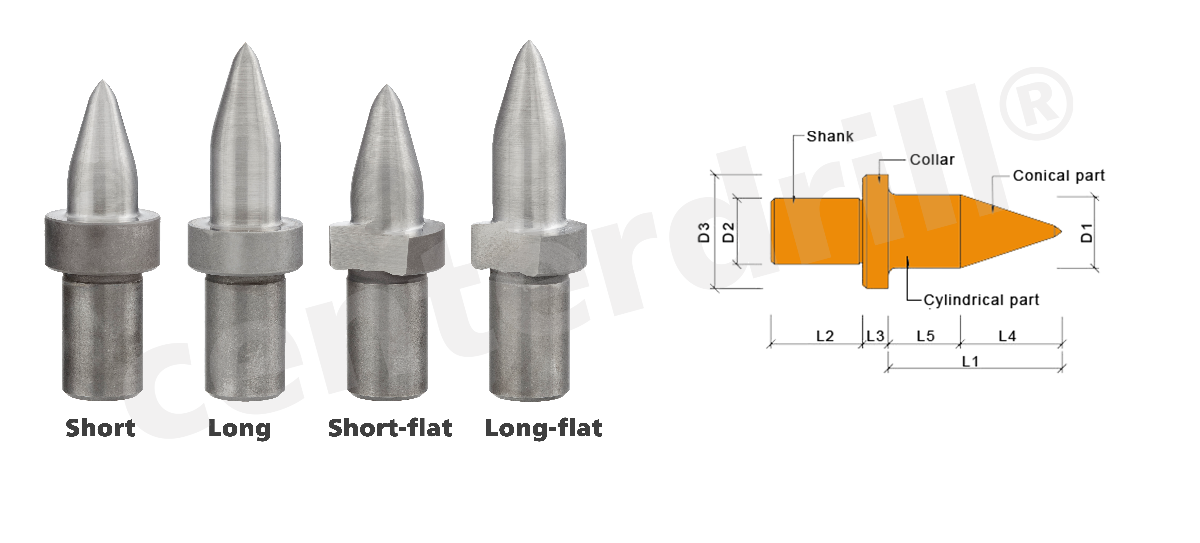

The Centerdrill standard types include four versions. Short, long, short-flat and long-flat. Depending on material thickness and desired surface decide the right type. The centerdrill tool short and long differ only in length of cylindrical part L5. When using these types the material displaced against the direction of feed remains on the surface of the work piece and forms a collar. Both types are also available in the flat version, they have cutters and remove the collar in the same operation. The result is a flat surface on the work piece.

During flowdrilling process we recommend to use our Centerdrill-release agents.

You can find all our products also in our Online-Shop!

Depending on your need you can receive a surface on your workpiece with collar or without collar (flat). Your choice of surface determines the right type of Centerdrill (with or without cutters). The flow drilling process eliminates the need for welded nuts, rivet nuts and the need for thread cutting in thin-walled applications.

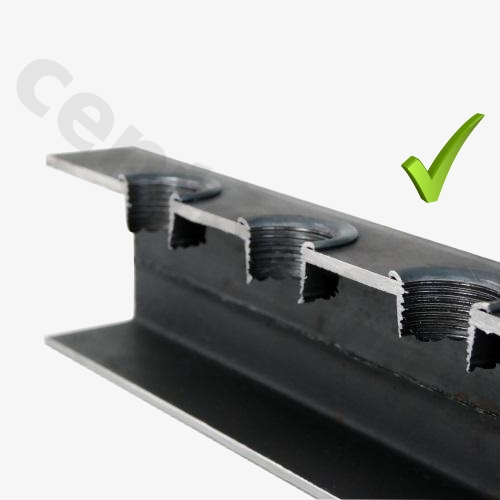

Surface with collar

Centerdrill with band

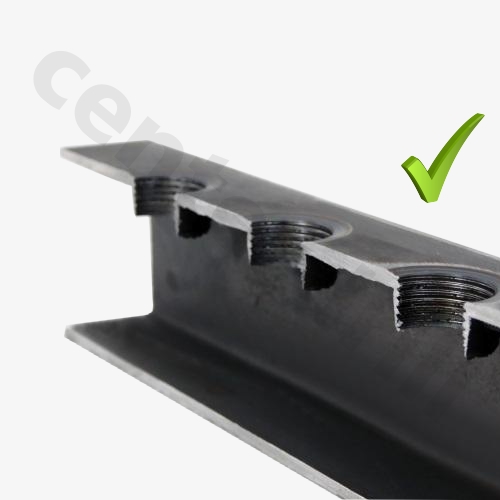

Flat Surface without collar

Centerdrill with flat cutter

The selection of the right centerdrill basically depends of the respective metal and its thickness and of the desired surface (plane or with collar). A further distinction is, whether a bushing shall be formed for a thread or a rim hole.

Short type: if an M8 thread shall be formed into a 1mm thick sheet of S235JR (St37/2) we recommend using the short type with Ø 7,3mm. A centerdrill with a cylindrical part that is only so long that the formed bushing will be slightly tapered at the run-out.

Long type: if the same application shall be realized in a 3mm thick sheet we recommend using the long type with Ø 7,3mm, because the cylindrical part L5 must be longer for this thickness.

Short-/long-flat type: if for above applications the surface of the work piece should be flat we recommend using the short-flat or long-flat centerdrill type.

Through hole: if a through hole for a plug connection is needed we recommend the long centerdrill types, because the cylindrical part is long enough for opening the bush completely.

Do you need help to choose the right centerdrill for your application? Then call us or use our tool finder => Centerdrill Explorer.

If our standard products cannot be used or are not adequate for your specific application, we also manufacture special centerdrill flowdrilling tools according to drawings. We are happy to advise you in your individual application needs. Please feel free to contact us!

Here you can see the most important information about the centerdrill process, also known as flow drilling process, friction drilling, flow forming, thermal drilling process or form drilling.

Centerdrill GmbH

Valterweg 19

D-65817 Eppstein

Tel. +49 (0) 6198/5858-97

Fax. +49 (0) 6198/5858-99

Mail: info@centerdrill.de

Tel. +49 (0) 6198/5858-97

Send directly to:

Mail: support@centerdrill.de

Send directly to:

Mail: order@centerdrill.de