Flow drilling is based on a combination of axial force and relatively high speed, which results in heat from friction. The frictional heat and high contact pressure plastify the material.

At the beginning of the flow drilling process you have to select the right Centerdrill for your application. In the first working step you will form a high-strength bush. In the second step you will form the thread with the corresponding Centertap threadformer. Your benefit: Production of bushes with threads in only two steps! Depending on the material and material thickness thousands of holes can be formed.

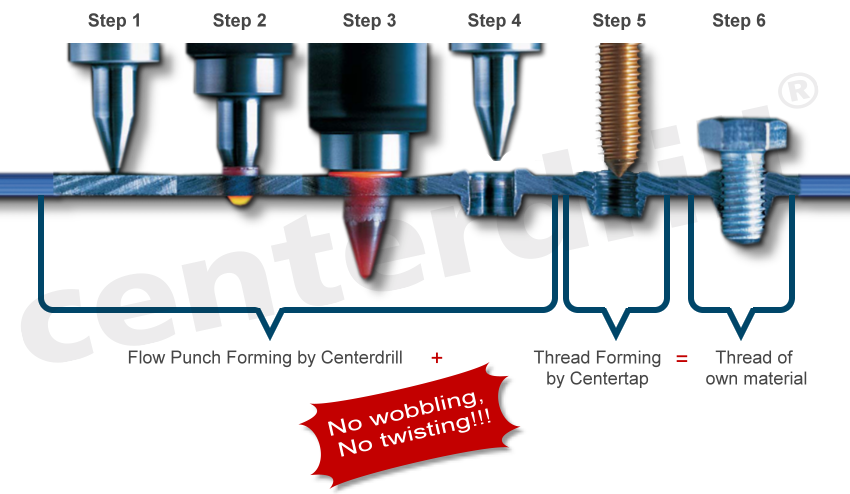

Step 1

The point of the centerdrill is positioned so that it just touches the material, then it is pressed down on the material with high axial force and speed.

Step 2

Feed pressure and speed generate the necessary frictional heat of approximately 600° Celsius that is needed to render the material plastic and thus formable. The centerdrill penetrates the material in a matter of seconds.

Step 3

The centerdrill displaces the metal horizontally and vertically, whereby the material is displaced primarily downward, producing a bushing. The feed pressure decreases and the feed rate increases gradually as the centerdrill penetrates through the metal.

Step 4

The centerdrill bush is finished. The material displaced against the direction of feed has been transformed into a sealing edge in the form of a collar. This collar can be removed by cutting during the same operation with the centerdrill flat version. The result is a flat surface on the work piece.

Step 5

The bushing is immediately ready without stock removal for chipless production of a thread using the centertap. The cold- formed thread increases the hardness of the material.

Step 6

The centerdrill result: loadable connections that can withstand high drawing forces. We replace rivet nuts, welding nuts and the thread cutting in thin metal sheets. No wobbling and no loosening anymore!

Our Centerdrill Explorer will help you to find the right centerdrill tool. In addition you will receive information about the RPM, feed rate and the required power for your machine, for a lot of materials und material thicknesses. All data are available for the flow drilling process as well as for the thread forming process.

Please click here: Centerdrill Explorer!

Or contact us directly. contact

Centerdrill GmbH

Valterweg 19

D-65817 Eppstein

Tel. +49 (0) 6198/5858-97

Fax. +49 (0) 6198/5858-99

Mail: info@centerdrill.de

Tel. +49 (0) 6198/5858-97

Send directly to:

Mail: support@centerdrill.de

Send directly to:

Mail: order@centerdrill.de