When working with a NC- or CNC-controlled equipment there is the possibility to significantly accelerate the execution of the production process. Depending of the machine design the feed rate as shown in the example - may be increased by increments during the individual process steps.

More CNC data are available on request.

| Centerdrill core hole-Ø (mm) |

max.wall thickness (mm) |

Centerdrill RPM* |

Tool length L1 (mm)** |

Total working path* (mm) |

working steps (mm) |

feed rate (mm/min) |

| M 6 - Ø 5.4 long (long-flat)* |

2,7 (3,0)* |

2400 | 13,5 | 12,0 (13,5)* |

0 - 2 2 - 4 4 - 6 6 - 11 11 - Ende |

150 250 350 550 200 (900)* |

| M 8 - Ø 7.3 long (long-flat)* |

3,5 (4,5)* |

2100 | 18,1 | 16,6 (18,1)* |

0 - 2 2 - 4 4 - 7 7 - 14 14 - Ende |

150 250 350 550 200 (900)* |

* With flat designs the work lengths increases by the height of the collar.

** Please check the length of the working part L1 of every new Centerdrill tool, because of our manufacturing tolerances.

Depending on the application and machine conditions the process speeds may also clearly vary from

the above information. Our application technicians are pleased to consult you.

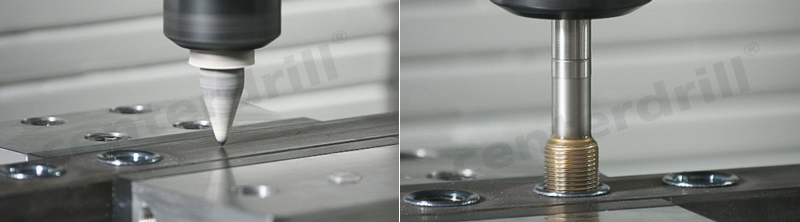

Example: Centerdrill 7.3 long for M8 + Centertap M8 in 2mm steel (S235JR). For approx.. 8000 threads (for your calculation [note: it depends on your process parameter and your applications]).

With Centerdrill + Centertap you will need only approx. 6 sec. for both operations together.

The advantage may be projected approx. about 40% time saving compared to other technologies, like welding- or rivet nuts.

Example: Centerdrill 7.3 long for M8 + Centertap M8 in 2mm steel (S235JR). For approx. 8000 threads (for your calculation [note: it depends on your process parameter and your applications]).

Do you know your material costs of press nuts, welding nuts or rivet nuts? Depending on the type it

will cost you between 0,06 and 0,16 EUR/pcs.?

With Centerdrill + Centertap your costs per thread will decrease. The costs are only approx. 0,0134

EUR per thread. This saving represents a material cost advantage of approx. 20% up to 90%.

Centerdrill GmbH

Valterweg 19

D-65817 Eppstein

Tel. +49 (0) 6198/5858-97

Fax. +49 (0) 6198/5858-99

Mail: info@centerdrill.de

Tel. +49 (0) 6198/5858-97

Send directly to:

Mail: support@centerdrill.de

Send directly to:

Mail: order@centerdrill.de