The flow drilling process creates high forces and heat, so it is essential that the workpiece and the Centerdrill are clamped very well. Additionally you should make sure that the heat will be removed before the heat enters the machine spindle and that your process ensures a high concentricity.

Our recommendation for an optimal flow drilling process

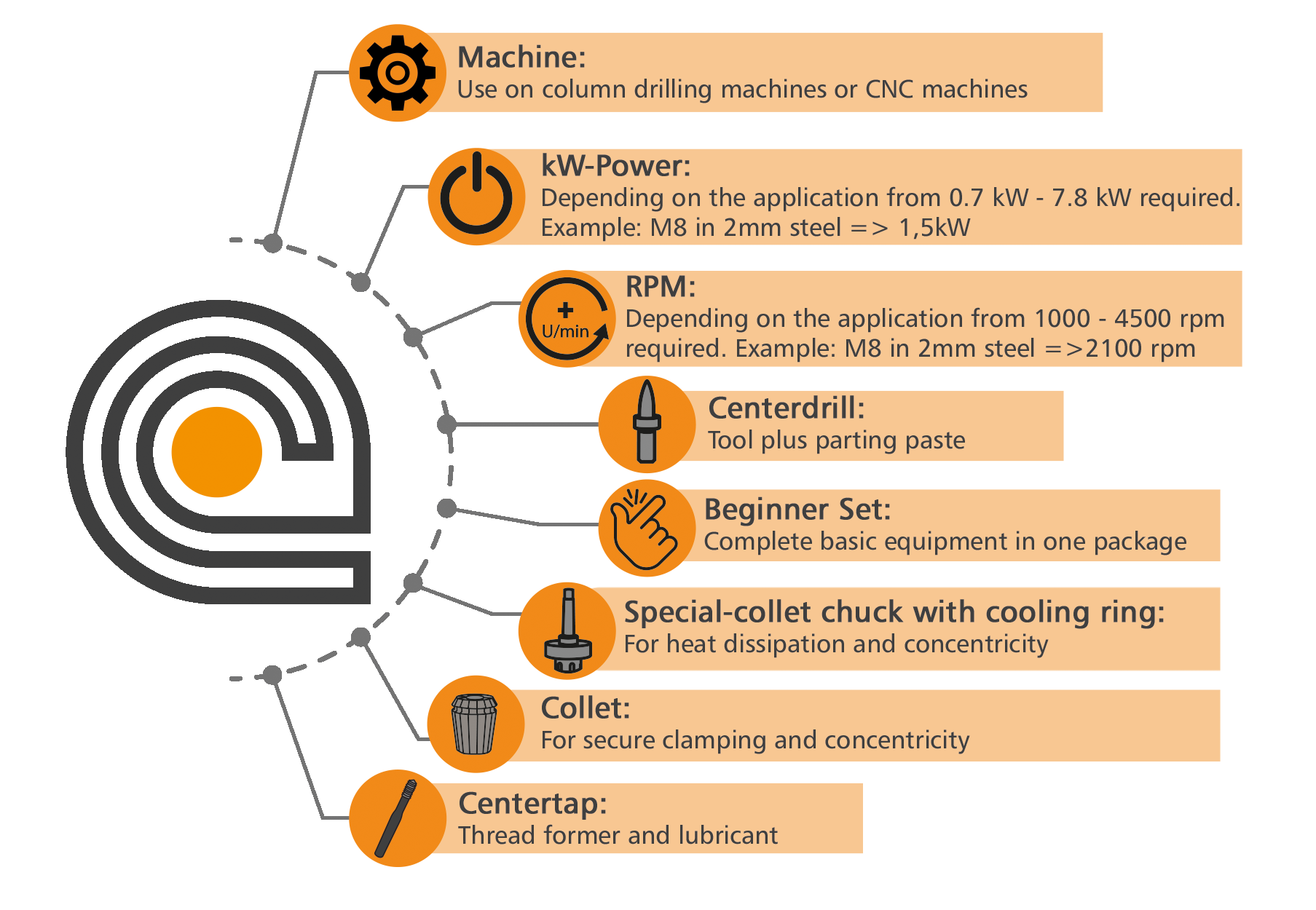

Necessary mechanical equipment Basically, any column drilling machine or NC/CNC machining center with sufficient power and speed are suitable for the flow drilling process with centerdrill (see Process data).

Collet chucks with cooling ring

Due to the extreme thermal fluctuation and the radial load it is absolutely essential to use our special collet chuck. The warmth generated during the process must not be allowed to enter the spindle but instead must be deflected or cooled. Customary three-part chucks can cause breakage of the centerdrill if it is not clamped centrally! For this reason a collet chuck with cooling ring was developed especially for flow drilling process with centerdrill, with which the heat can be dissipated ideally and a secure clamping can be ensured.

Various types are available. The collet chuck MC2 is standard for centerdrills up to a shank to Ø 14 mm. For bigger sizes we recommend an MC3 holder. More collet chucks like SK30, SK40, HSK63, etc. are available. Also, please keep in mind that it can be useful to use reducing sleeve! (see collet chucks).

Collets

For optimum concentricity and secure connection of the centerdrill it is essential to use a collet. Together with our special collet cuck you have ideal prerequisite for a safe process. (see collets).

Centerdrill - Flow Punch Former

At the beginning of the flow drilling process you have to select the right Centerdrill for your application. In the first working step you will form a high-strength bush. In the second step you will form the thread with the corresponding Centertap threadformer. Your benefit: Production of bushes with threads in only two steps! What is the right type of Centerdrill for you? You can find it here, in our Centerdrill Explorer! In just a few clicks!

Release agent for flow drilling process

Moistening the centerdrill with our highly heat-resistant parting paste, matched to the respective material to be processed, is important for the life of the centerdrill tool. The working part will be protected and material adhesion will be reduced during the flow drilling process. You can apply the release agent manual or by spraying system. It is suitable for all materials like steel, stainless steel, brass, aluminum, copper, etc. (see release agent)

Here you can find everything you need for a quick start. Take a look at our Beginner-Set.

Required mechanical equipment for thread forming with centertap

Any customary thread cutting device can be used for thread forming. However, a processing speed is required that is between 3 to 10 times faster than for thread cutting. If a machine is not available on which the direction of rotation of the spindle can be switched, we recommend using a special thread cutting unit.

Thread tapping chuck

For location of the thread formers in machines with switchable direction of rotation we recommend a chuck with longitudinal compensation in tensile and compressive direction and "pressure point mechanism". This will allow operation of the thread former independent of the axial force and compensate for a possible trailing of the machine spindle in the reversal point. Combined with the appropriate quick-change unit with overload coupling, this ensures the safety function both for the tool as well as for the machine spindle.

Centertap threadformer

In the first working step you will form a high-strength bush with our Centerdrill. In the second step you will form the thread with the corresponding Centertap threadformer. Your benefit: Production of bushes with threads in only two steps! Get bushes out of the original material, with high extraction forces. No more wobbling and no loosening!

Lubrication during thread forming

The use of our lubricant is highly recommended during thread forming. It should be applied before each operation on the centertap. Our lubricant is ecologically tested according to DIN.

Centerdrill Beginner-Set:

The easy way to start with the flow drilling process. Except a sufficient machine you get everything you need. You can expect cost savings compared to the single sourcing!

*price per size and type different

Several collet chucks are available. MC2, MC3, SK30, SK40, HSKF63, etc.

Also, please keep in mind that it can be useful to use reducing sleeve!

*Preis je Größe und Typ verschieden

Centerdrill GmbH

Valterweg 19

D-65817 Eppstein

Tel. +49 (0) 6198/5858-97

Fax. +49 (0) 6198/5858-99

Mail: info@centerdrill.de

Tel. +49 (0) 6198/5858-97

Send directly to:

Mail: support@centerdrill.de

Send directly to:

Mail: order@centerdrill.de