Basically, any column drilling machine or NC/CNC machining center with sufficient power and speed are suitable for the flow drilling process with centerdrill.

Required process data for the flow forming and thread forming process

Reference values for material S235JR (St37/2) with 2mm wall thickness

Metric ISO thread per DIN 13 |

||||||

| Centerdrill Flow Forming | Centertap Thread Forming | |||||

| Thread |

core hole Ø mm |

RPM | Torque Nm |

machine output kW |

RPM | Torque Nm |

| M3 x 0,5 | 2,7 | 3000 | 2,5 | 0,7 | 1500 | 1,3 |

| M4 x 0,7 | 3,7 | 2600 | 3 | 0,8 | 1100 | 3 |

| M5 x 0,8 | 4,5 | 2500 | 4 | 0,9 | 900 | 4,9 |

| M6 x 1 | 5,4 | 2400 | 5 | 1,1 | 800 | 9,3 |

| M8 x 1,25 | 7,3 | 2100 | 7 | 1,5 | 600 | 19 |

| M10 x 1,5 | 9,2 | 1800 | 10 | 1,7 | 380 | 39 |

| M12 x 1,75 | 10,9 | 1500 | 14 | 1,9 | 300 | 50 |

| M14 x 2 | 13 | 1500 | 16 | 300 | 55 | |

| M16 x 2 | 14,8 | 1400 | 19 | 2,4 | 200 | 57 |

| M20 x 2,5 | 18,7 | 1200 | 29 | 3,0 | 160 | 105 |

Whitworth pipe thread |

||||||

| Thread | core hole Ø mm |

RPM | Torque Nm |

machine output kW |

RPM | Torque Nm |

| G1/8'' | 9,2 | 1800 |

10 |

1,7 | 380 | 13 |

| G1/4'' | 12,4 | 1600 | 16 | 2,1 | 280 | 34 |

| G3/8'' | 15,9 | 1400 | 24 | 2,6 | 200 | 46 |

| G1/2'' | 19,9 | 1200 | 32 | 3,2 | 140 | 94 |

| G3/4'' | 25,4 | 1000 | 55 | 3,8 | 100 | 128 |

Please note:

Centerdrill flowdrilling in stainless steel:

Centerdrill flowdrilling in non-ferrous metals:

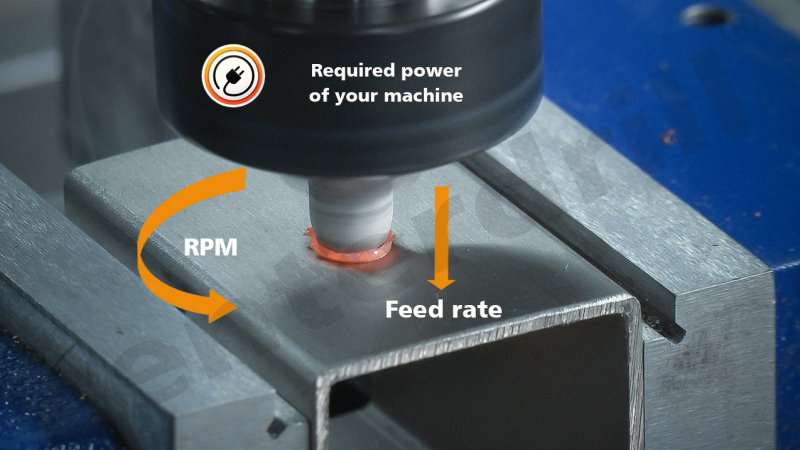

Feed rate for Centerdrill flowdrilling:

Depending on the application the machine conditions and the process data may also clearly vary from the above information. Our technicans are pleased to consult you.

All in one – Tool finder and process database for your application!

Our Centerdrill Explorer will show you the right RPM, feed rate and the required power for your machine, for a lot of materials und material thicknesses. All data available for the flow drilling process as well as for the thread forming process.

For example these data include specifications for following materials: stainless steel, steel, aluminum, copper and brass and for the material thicknesses between 0,8-12mm.

Centerdrill GmbH

Valterweg 19

D-65817 Eppstein

Tel. +49 (0) 6198/5858-97

Fax. +49 (0) 6198/5858-99

Mail: info@centerdrill.de

Tel. +49 (0) 6198/5858-97

Send directly to:

Mail: support@centerdrill.de

Send directly to:

Mail: order@centerdrill.de